Scroll to continue

Scroll to continue

Shell is working with Scuderia Ferrari to develop future fuels and lubricants that will help improve efficiency and reduce carbon emissions, whilst at the same time delivering optimum performance.

Shell is delivering and implementing innovations at the racetrack that are designed to help contribute to the decarbonisation of Formula One.

From 2021 at all European races, Shell started providing Scuderia Ferrari with a biofuel for its trackside generators that can help reduce CO2 emissions by up to 50% compared to the fuel used in the previous year3. The fuel is made of 60% renewable feedstocks, such as agricultural waste and used cooking oils, and 40% Shell GTL (gas-to-liquids) fuel, derived from natural gas.4

Shell is proud to support Circuit Zandvoort and the Formula One Heineken Dutch Grand Prix by supplying all event generators with Shell GTL fuel. This alternative diesel fuel burns more cleanly than conventional crude oil-based diesel, resulting in a reduction of local emissions.

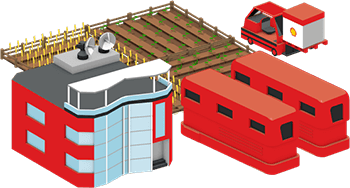

In 2021, Shell has given its Trackside Laboratory (also known as the Shell Track Lab) a refresh, using lightweight materials throughout to ensure weight-saving in overall transportation as it travels around the world, lowering the CO2 emissions from transportation.

Shell's commitment to contributing to the decarbonisation of Formula One, in collaboration with its innovation partner Scuderia Ferrari, also includes a number of initiatives beyond the racetrack.

In 2021, Shell started using R33 Blue Diesel in its logistics truck that delivers fuel products to all European races, helping reduce CO2 emissions by at least 22% compared to conventional fossil diesel. R33 Blue Diesel is composed of 33% certified renewable components strictly derived from waste and residues, like used cooking oils.

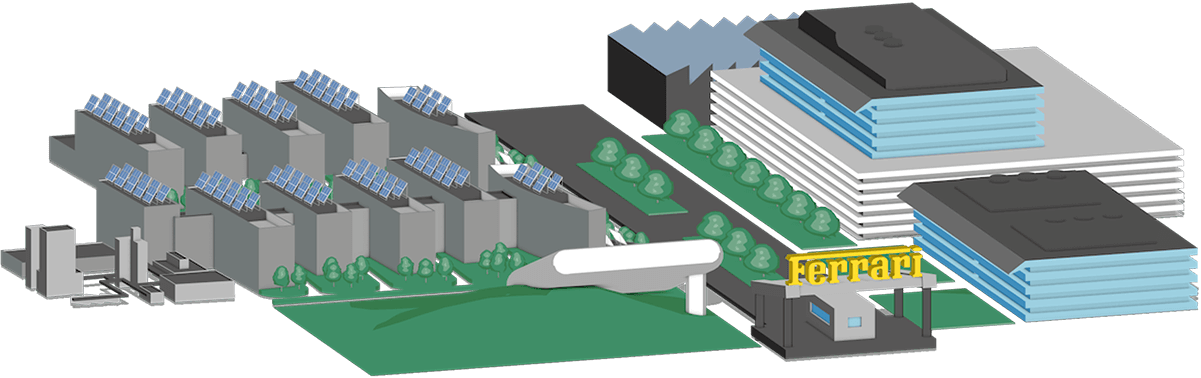

Shell provides natural gas and certified renewable electricity to Ferrari's Maranello plant to help power Scuderia Ferrari operations.